Engineering

- Design

guide & review - Vibration

Analysis - Noise

Analysis - URN

Analysis - Measurement, Evaluation and Trouble-shooting

Design

Guide & Review

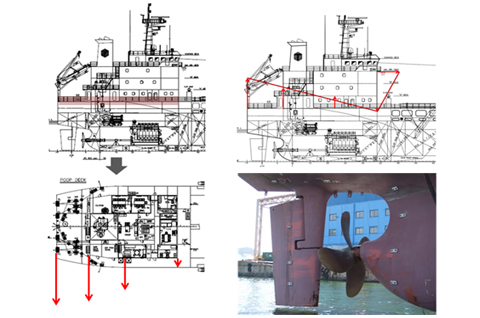

Ensuring the achievable and reasonable design targets for on-board machinery and structures at the design stage can guarantee successful constructions which meet building specifications and comfortable environments in ships and offshore structures. Our experienced engineers supply the following consulting services to owners and builders for noise, vibration and underwater radiated noise performances.

- Guidance on major equipment foundation & deck structure for anti-resonance design

- Suggestion for vibration & noise criteria of machinery & rubber/wire-rope mount

- Design review & modification of structures to satisfy building specification

- Offering the optimum design modification method considering acceptable building & design environment

- Review maker’s & builder’s technical documents

-

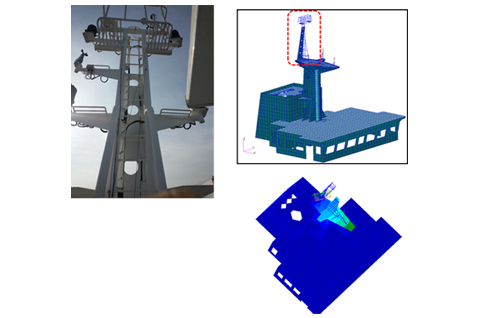

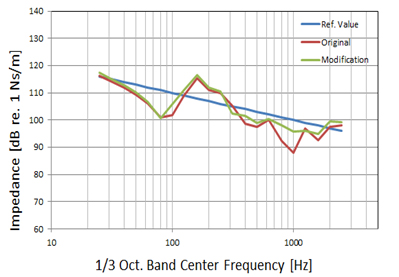

Design modification result on

dynamic stiffness of equipment foundation

-

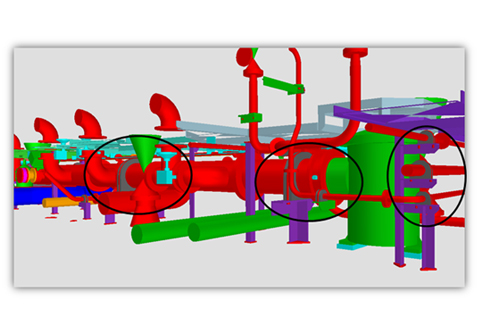

Design modification to reduce flow-induced vibration on pipe lines

Vibration

Analysis

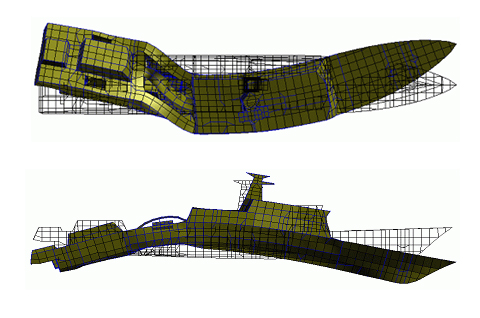

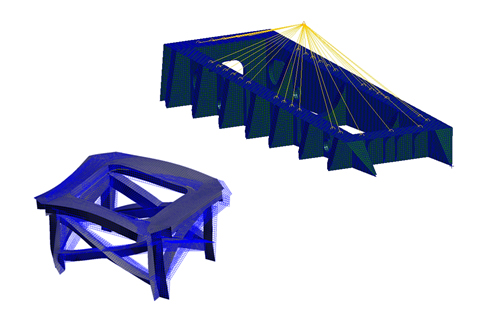

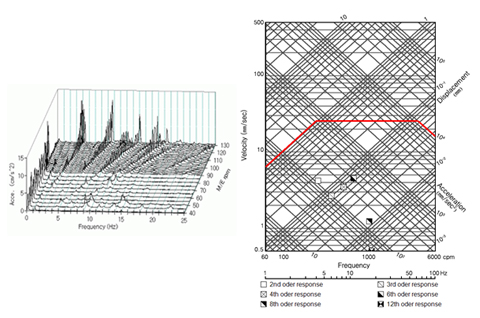

From dynamic stiffness estimation to forced vibration response analysis, precise and effective vibration analysis using 3D FEM can be carried out depending on our customers’ demands. We have experiences over 80 vibration projects for ships and offshore structures since 2000 and can help customers to design and obtain high quality low vibration environments.

- Vibration analysis using 3D finite element method

- Confirmation of anti-resonance design for ships & offshore structures including machinery foundation and deck structures

- Prediction of vibration levels on structures by forced vibration analysis

- Estimation of dynamic stiffness on machinery foundations & deck structures

- Identification of dominant vibration transmission paths and structural modification by structural intensity analysis

-

Natural and forced Vibration Analysis

-

Anti-resonance check and dynamic stiffness calculation for machinery foundations & deck structures

-

Identification of dominant vibration transmission path using structure intensity analysis

Noise

Analysis

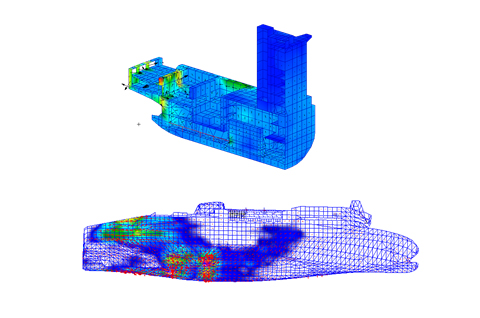

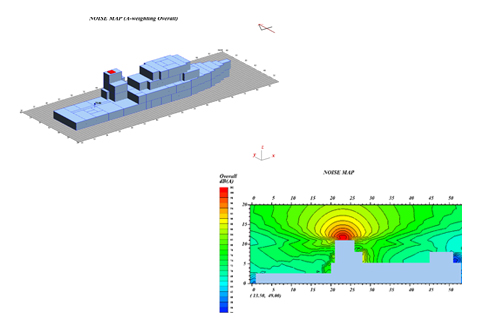

CreaTech considers all noise propagation mechanisms in noise analysis using 3D computation S/W and design information. Predicted noise levels at the interested areas are compared with the related noise criteria, and economic & efficient countermeasure methods are provided based on the calculation results if necessary. The detailed information for noise analysis is listed below

- Noise analysis using 3D GUI computation S/W based on advanced analysis theories

- Outdoor noise analysis including the effect of evacuation alarm sound and the performance of human residence

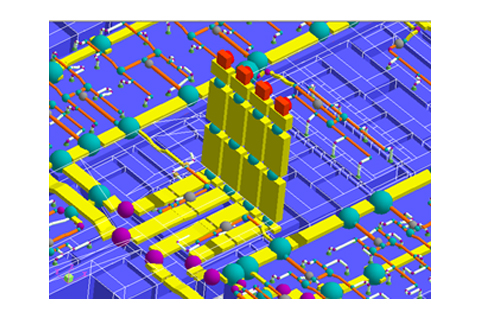

- Noise analysis of HVAC system considering operation condition and detail components

- Indoor noise analysis caused by structure-borne and air-borne noise sources

- Precise analysis of indoor sound field for source room

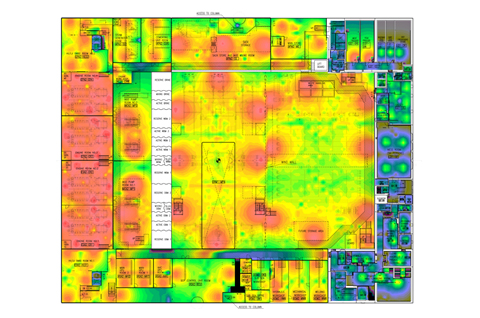

- Sound coverage study for PAGA system considering speech transmission index

-

Indoor noise analysis considering structure-/

air-borne transmission path

-

Outdoor noise analysis

-

HVAC system noise analysis

-

Sound coverage study for PAGA system

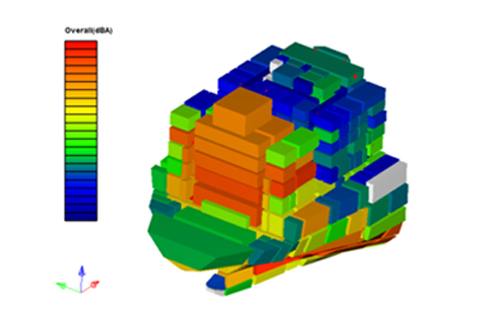

URN

Analysis

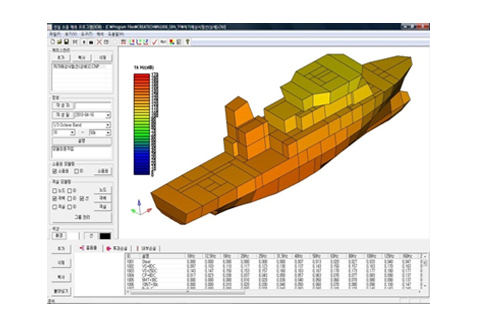

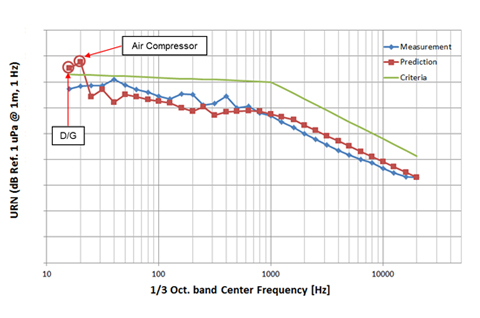

For research vessels and naval ships, the URN (Underwater Radiated Noise) performance has become to be very important as an aspect of the successful research & accomplishment of military mission. Our URN analysis considering all of the URN mechanisms including the vibration and noise produced from on-board machinery, structural characteristics of hull and direct underwater noise induced by the propeller can guarantee the successful building of customer’s silent vessel.

- TFM(Transfer Function Method) applied at the early design stage considering typical ship’s URN characteristics

- SEA(Statistics Energy Analysis) method at the detailed design stage using real ship’s design data

- Strongly related with vibration/noise analysis technology and also field inspection & engineering

-

URN Analysis S/W:ENPro-URN

-

URN Comparison between analysis and measurement

Measurement, Evaluation

and Trouble-shooting

CreaTech’s engineers with rich experiences in the various industrial fields and possessing the precision equipment will conduct rigorous assessment, measurement and diagnosis for troublesome vibration/noise. In addition, we will present the most economical and efficient countermeasures based on the measurement results

- Measurement of vibration, noise and URN performances

- Performance evaluation according to related regulations and guidelines

- Trouble-shooting in field tests and factory acceptance tests

- Technical representative for owners and builders on board and site

-

Vibration test

-

Impact modal test

-

Noise test

-

Measurement & Evaluation

-

Trouble-shooting

-

Field test and evaluation